Industrial Minerals:

INTRODUCTION

Slate powder and granules are purpose made Inert Mineral Fillers produced from high-quality slate, extracted from the Rockmart Slate Quarry; situated in Rockmart, Georgia.

Rockmart Slate is of excellent quality, highly resistant to atmospheric attack, and meets the exacting requirements of current industry standards; which are particularly concerned with durability. It has high resistance to acids and staining.

APPLICATIONS

- Paints and Coatings

- Rubber and Plastics

- Adhesives and Sealing compounds

- Surface Coatings/Dressings

- Automobile Underseal

- Roofing Granules and Back Surface coating

- Roofing Felts

- Pipe Protective Coatings

- Mastics and Resins

- Damp-Proof Courses

- Reconstituted Roofing Tiles

- Concrete Filler

- Marine Compounds

BENEFICIAL PROPERTIES

- Stability and Inertness

- High specific gravity and bulk density

- Low abrasion characteristics

- Low absorption charactersitics for both oil and water

- Consistency of particle size and the ability to produce a variety of closely-sized fractions over a wide overall range

- Sound-deadening and insulation qualities

PARTICLE SHAPES

Because of the flaky habit of the component minerals, the particles of slate powder and granules are also flaky - not sharp or angular. They have a thickness of one-quarter to one-tenth of their breadth. In many applications, this characteristic has been found to have reinforcing properties. The particle shape gives a high specific surface, and consequently, good covering capacity.

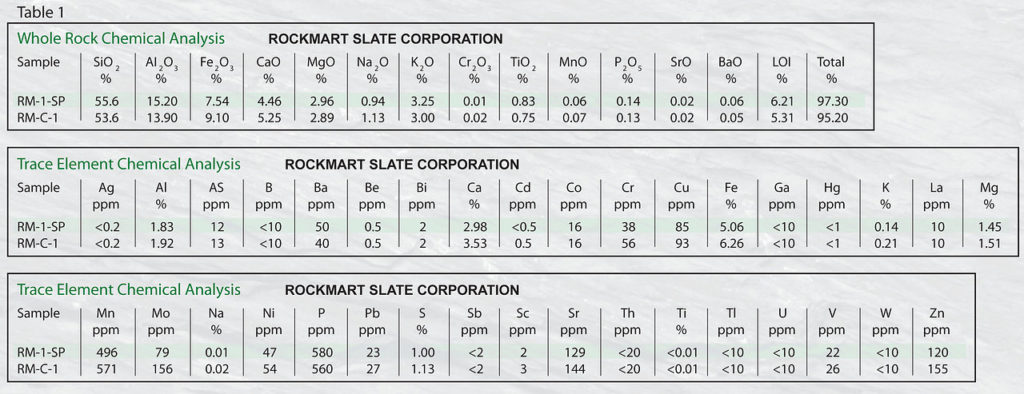

CHEMICAL ANALYSIS

Table 1 shows the distribution of the chemical analysis compounds in the component slate minerals. It is these abundant, stable, low abrasive, low moisture absorption, smooth, platy minerals that make Rockmart Slate powder & granules an ideal mineral filler or carrier for many purposes.

CALL FOR CUSTOM SOLUTIONS!

Multiple sizes and blends available. Call us by dialing (770) 684-6583 now!